PRODUCT

Jacket heater

A combined unit comprising a heater and insulation material that eliminates needless time and effort expended on heat tracing and insulation work to realize outstanding running costs. Compatible with almost any shape.

Features

Heat-resistance temperature: Up to 450℃ max.

*Please ask us about higher temperatures.

- The heater and insulation material comprise a single unit, eliminating needles time and effort expended on insulation work and keeping costs down.

- The insulation material used is carefully selected to ensure a low surface temperature and keep running costs down.

- Thanks to the design that is compatible with materials matched to applications and a wide range of fittings, we can propose specifications to match all kinds of requirements.

- Ultra-fine nichrome wire is sewn into the entire cover to ensure outstanding service life and temperature distribution balance.

Applications

- Heating and thermal insulation of piping in semiconductor manufacturing equipment.

- Heating and thermal insulation of piping equipment (e.g. Elbows, piping, valves flanges, U-shaped pipes, V-shaped pipes, valve, bent pipes, branch pipes, hoppers)

- Heating and thermal insulation of tanks (e.g. Distillation tanks, mixing tanks, chemical reaction tanks, storage tanks, drums, pails, vacuum containers)

- Heating of all kinds of vacuum devices

- Thermal insulation of equipment used in cold regions

- Heating and thermal insulation of complicated experiment and research apparatus and special glass apparatus

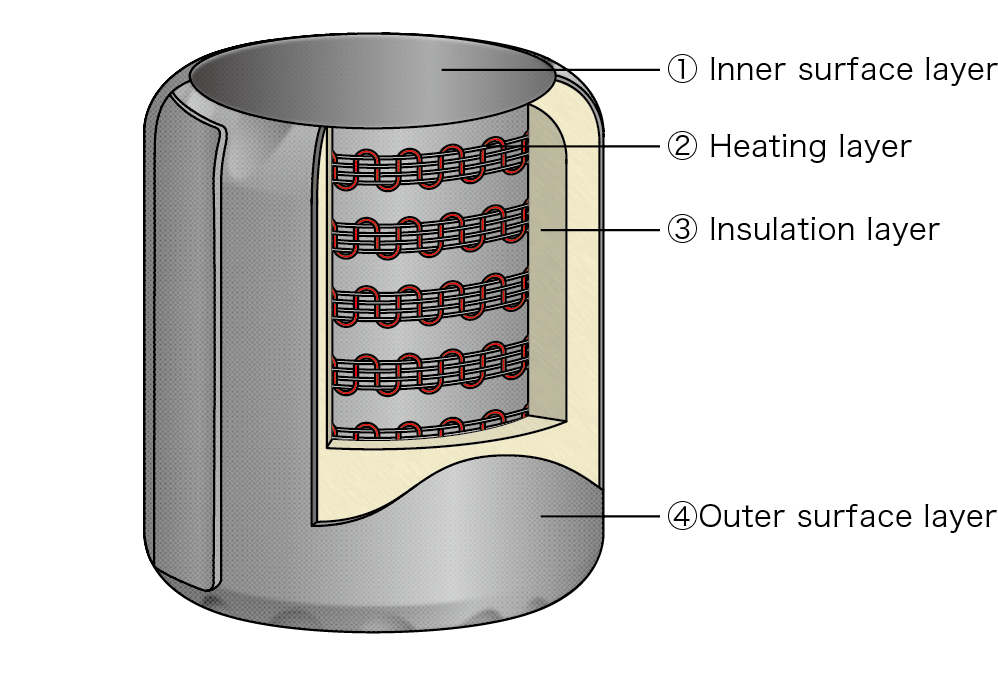

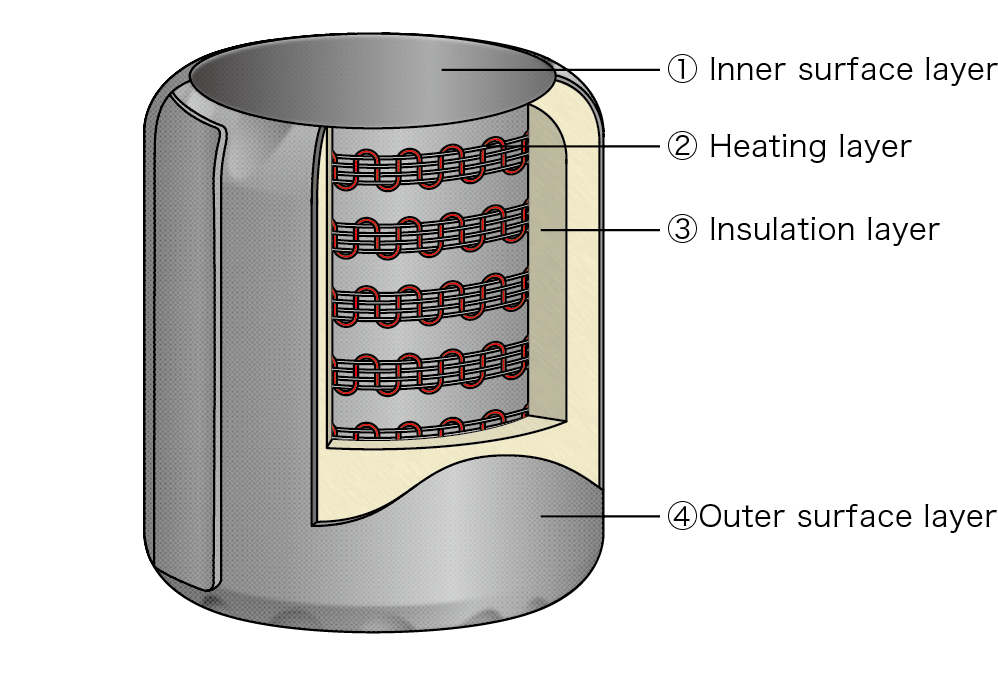

Structural Drawing

Typical Materials

| 構造 | 材料 |

|---|---|

| ① Inner surface layer | Silicone coated cloth, glass cloth, non-asbestos cloth, alumina cloth |

| ② Heating layer | Nickel chrome wire + E-glass braid, nickel chrome + alumina fiber braid |

| ③ Insulation layer | Glass wool, half-silicone mat |

| ④ Outer surface layer | Silicone-coated cloth, aluminum upholstery cloth |