Precautions

Safety Precautions

Heated hose & Heated tube

Do not put easily ignited substances (First or second class petroleum) into heated hoses and heated tubes or use them in places where there are flammable gases such as propane or city gas, or where there may be gas leaks. Doing so may cause ignition, resulting in serious accidents.

In addition, avoid using heated hoses in places where they may be directly exposed to water or humidity, or outdoors.

- Heated hoses and heated tubes are not explosion-proof. Never put easily ignited substances into heated hoses, or use them near easily ignited substances or materials.

- Standard heated hoses and heated tubes are not moisture or dust proof.

- Switch the power supply off before installation Always switch the power supply off and check that there is no current flow before installing hoses. Working with electric current flowing may result in electrocution and is extremely dangerous.

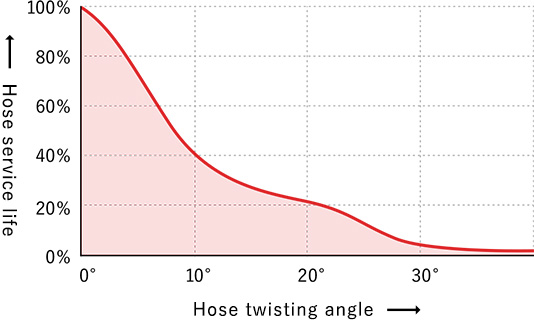

- Do not twist hoses.

Pressurization of twisted hoses may shorten the hose service life or loosen joints. Take all due care to make sure that hoses are not twisted during installation.

Procedure for installation of standard specification hoses with cap nuts

①Mount a male nipple at the place or on the device where the hose is to be installed.

②Tighten the cap nut being careful not to turn the hose body. - Do not lap wind or bundle heated hoses with the power on.

Never lap wind or bundle one or more heated hoses with the power on. Doing so may cause excessive temperature at overlapping points, damage the products or cause fires and is extremely dangerous. - Do not bend hoses tightly

Bending hoses to less than the minimum bending radius may cause damage to the inner pipe, support layers, heaters or sensors, or severed wires.

Always use hoses at a radius larger than the specified minimum bending radius.

In addition, make sure that hoses are straight for a distance of approximately 300mm from the ends of joints. If keeping hoses straight is not possible due to factors such as the shape of the connected equipment, install an elbow to change the angle and avoid sharp bends. - Do not stretch hoses.

Stretching hoses beyond their free length may cause reduced pressure, over stretching or damage to fixtures. - Tighten joints firmly.

Joints should be tightened firmly by hand. Insufficient tightening may result in fluid leakage. - Using hoses arranged in a straight line

When hoses are pressurized, the length may change by approximately ±3%. Thus, when hoses are arranged in a straight line, they should be allowed to sag a little when installed. - Do not use wire or bundling bands to secure heated hoses.

Doing so may result in application of pressure in parts of the hose, adversely affecting the heater and causing defects. - Avoid settings of the same hose that will result in different ambient temperatures (e.g. Covering only part of the hose with insulation material, exposing only part of the hose to air conditioning, using two or more hoses bundled). Doing so may result in failure to reach the set temperature or excessive heating, causing defects or hose malfunctions due to damage to internal pipes.

After being set in place for a certain length of time, hoses will develop curvature matching the orientation in which they have been installed. After disconnecting hoses to perform tasks such as replacing, inspecting or repairing connected devices, make sure that hoses are reset in their original orientation. Always be sure to switch off the power supply and check that there is no current flow when disconnecting and resetting hoses.

Flexible heater

- The flexible is not explosion proof.

Never install on easily ignited objects or use near easily ignited objects or materials. - Flexible heaters are not waterproof.

Avoid use and storage in places where there is high humidity or outdoors. - Switch of the power supply before installing.

Always switch of the power supply before installing flexible heaters and make sure that there is no passage of current flow.

Installing flexible heaters with the power switched on may result in electrocution and is extremely dangerous. - Do not touch the heater during heating.

The surface of the heater becomes extremely hot during the heating process. Never touch heaters directly. Doing so is extremely dangerous and may result in burns. - Do not expose heaters to excessive shock.

Since the heat-generating element comprises ultra-fine heater wires, undue shock may result in severance of wires, Be careful to avoid excessive shock caused by placing objects on, bending or twisting heaters. - Never stack or mount heaters loosely.

Doing so may result in abnormal temperature rises and cause problems such as electrical leakage.- When installing flexible heaters

- Check for any accumulations of water, oil, dust or other contaminants on the part where the heater is to be installed. Completely remove any such accumulations with a cloth or other suitable means.

- Install the heater (In principle, thermal fuses should also be used in the middle and where otherwise necessary.)

- Install an earth wire on the device to be heated.

- If necessary, set insulation material in place evenly.

- Connect the lead wire after completing all the above steps.

Flexible heaters may produce odors or smoke immediately after purchase.

Smoke or odors are produced when adhesive paste used in the manufacturing process burns.

High pressure thermoplastic hose

●Avoid piping that involves extreme bending or twisting.

Unreasonable piping that involves tight bends may result is kinks (breakage). Always ensure that piping is arranged at more than the specified minimum bending radius.

In addition, securing twisted hoses may result in shortened service life, damage or loose joints due to hose movement or repeated pressurization.

Be careful to avoid twisting hoses when piping.

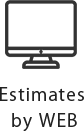

Reference: Graph showing changes in hose service life resulting from twisting. (Comparison with our company's products)

The service life shortens significantly with increased twisting.

Make sure that hoses are firmly secured when installing.

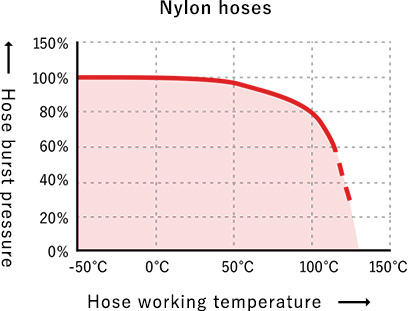

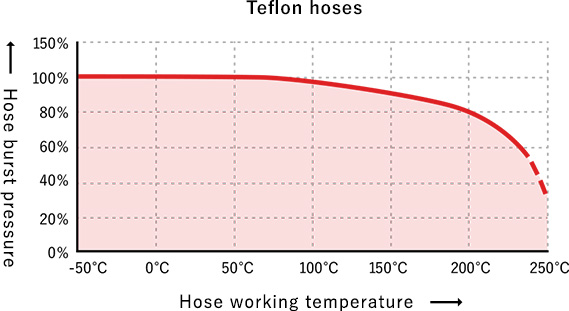

●Please bear in mind that pressure resistance may deteriorate depending on the working temperature.

Hoses each have a set working temperature range and increases in the working temperature beyond the range will result in deterioration of pressure resistance.

Although use in room temperature environments will not result in any problems, care must be taken in high-temperature environments or when using high-temperature fluids.

The hose burst pressure (BP) decreases with increases in ambient or working temperatures.

While hoses can be used at the specified pressure up to maximum working temperatures specified by the manufacturer, please remember that the hose service life will shorten as the working temperature increases.

●Allowance should be made with length when selecting hoses.

When pressurized, hoses may expand or contract by approximately ±3%. Accordingly, please allow a suitable slackness to avoid exposing hoses to tensile stress.

Joints must be firmly connected by hand.

Tighten high-pressure hose joints firmly by hand. Any looseness may result in fluid leakage. In addition, excessive tightening may cause damage to joints.

See the table below for details.

| Pipe thread:PF(G) | 1/8 | 1/4 | 3/8 | 1/2 | 3/4 | 1 |

|---|---|---|---|---|---|---|

| Tightening torque N.m(kg f/m) |

15(1.5) | 25(2.5) | 34(3.4) | 64(6.1) | 132(13.2) | 196(19.6) |

| Unified thread:UNF | 7/16-20 | 1/2-20 | 9/16-18 | 3/4-16 | 7/8-14 |

|---|---|---|---|---|---|

| Tightening torque N.m(kg f/m) |

25(2.5) | 30(3.0) | 40(4.0) | 50(5.0) | 60(6.0) |

●Be careful of damaged joints

Before installing high-pressure hoses, check for damage of joints, nipples used (adapters), the metal touch part of the connected device and screw thread ridges. Replace any damaged nipples and joints on the connected device.

Using damaged parts may result in fluid leakage. Always use sealing tape with PT (tapered) screws.

See the table below for details.