About heated hoses

From low to high temperatures,

from extremely low to ultra-high pressure

Heated hose is our company main product which provides constant temperature transfer by controlling fluid temperature according to operating conditions. Evenly braided with nichrome wire, the heater can be set within a range of 0℃ to a maximum of 400℃ and keeps differences in the temperature distribution of the internal wall to a minimum value.

With a maximum working pressure of 35MPa, heated hoses are used in various fields including dispensers, resin molding, food and medical equipment manufacturing.

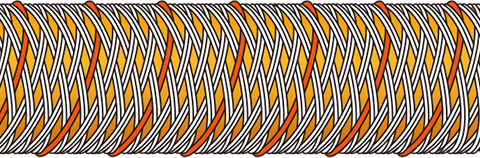

Heater Structure

Heaters are braided with E-glass fiber to ensure an even inter-heater pitch so that heaters do not dislocate when the hose moves.

In addition, the structure also prevents partial overheating, short circuits and ground faults.

Applications

- Hot melt equipment

- Bonding and adhesion for packaging, bookbinding, plywood, disposable diapers, etc.

- Dispensers

- Devices, epoxy resin, silicone

- Automotive applications

- Transfer of butyl rubber and urethane

- Resin molding

- Transfer of high-viscosity resins (e.g. PP, PE, Acrylics, PVC), multi-layer molding

- Science

- Environment-related applications: Exhaust gas sampling and analysis equipment

- Food and medical equipment-related

- Transfer of substances such as chocolate, wax, oil and cosmetics

- Painting industry

- Hot air, hot sprays

- Next-generation energy

- Fuel cells, optical fiber

- Others

- Oil, grease, asphalt, tar enamel, ink vapor, condensation, antifreeze, etc.

External Specifications

-

Standard type

-

Heavy duty type

-

Flame retardant shrinkable tube type (Drip- and dust-proof)

-

Stainless steel shield type

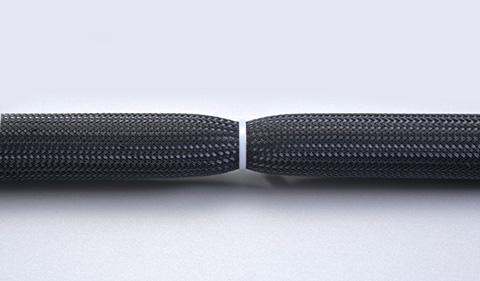

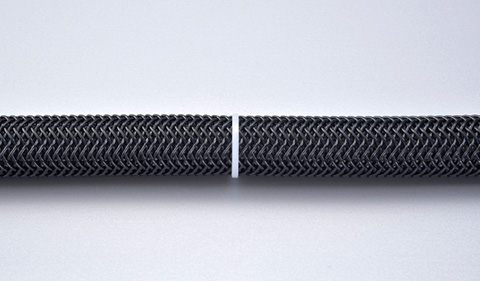

Anti-damage, anti-break and surface temperature reduction

Our company's original braiding technology is applied to the outer layer to enhance damage and breaking resistance performance.

The structure also enables reduction of the hose surface temperature.

Anti-break (Having a similar effect to entire length spring equipped hose.)

-

Standard type

-

Heavy duty type

Ensures protection when fastened with bundling bands.

-

Standard type

-

Heavy duty type

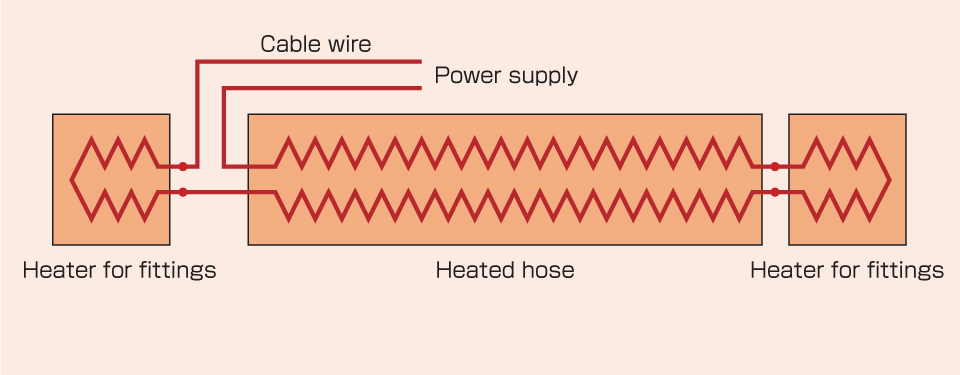

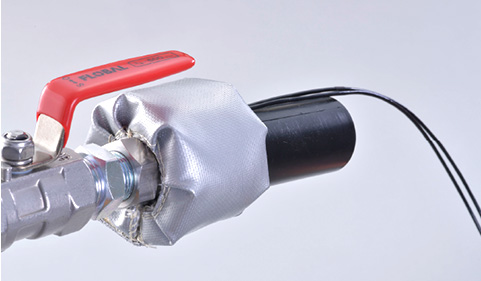

Heater for fittings

Since the joints of the standard type are not heat treated, problems such as drops in the temperature or melting failure of the fluid may arise.

In such cases, joint heaters are effective.

Because the hose body and heaters are wired in series, temperature is adjusted together with the hose body, eliminating the need for a separate heat-regulating system.

Wiring diagram

-

Jacket heater type

-

Cord heater type